Energy & Emissions

Climate change is one of the biggest challenges of our times. Our business activities generate greenhouse gases. We see it as our duty to help prevent or mitigate climate change for a world worth living in – today and tomorrow. Our goal is to achieve climate neutrality for the Eppendorf Group. To advance toward that aim, we have pledged our support for the goal of the Paris Agreement of limiting global warming to less than 2 degrees Celsius between now and 2100.

The act of manufacturing our products generates CO2 emissions along the entire value chain. We aim to reduce these emissions. Our efforts focus chiefly on CO2 emissions from our own production and administration sites, as well as on CO2 emissions associated with the use of our products by our customers.

Energy-efficient products and technologies are increasingly in demand among our customers. That is why we take energy efficiency into consideration early on in our development processes. From our perspective, investing in climate action and energy efficiency will pay off in the long term, including financially.

Countering risks, meeting requirements

Climate change can bring uncertainty in terms of planning and investment. With an eye to these factors, we are taking action to protect the climate and lower future risks to our business model. For example, increasing the energy efficiency of our processes has the beneficial side effect of lowering our dependence on energy prices, which fluctuate. We also meet the increasingly stringent requirements set by our stakeholders. Our customers in particular – as well as our employees, the owners’ families and legislators – expect us to show strong support for climate action and report transparently on our carbon footprint. Ultimately, our climate action measures will also help implement the principles of the Global Compact.

Our climate strategy

Our ambition is to achieve climate neutrality for the Eppendorf Group. This is why we have developed an ambitious climate strategy aligned toward the goal set by the Paris Agreement of limiting global warming to less than 2 degrees Celsius between now and 2100. As a first step, we began compiling a carbon footprint for the entire Eppendorf Group in 2021. We collected data on the CO2 emissions generated by our business activities (Scope 1 and 2), CO2 emissions from self-contracted transports and business air travel (Scope 3, categories 4, 6 and 9).

From this initial carbon footprint, we derived a Group-wide climate target. We aim to achieve climate neutrality for the Eppendorf Group by 2028. This overarching goal is to be achieved by way of various interim goals, which have been set out in a road map of short- to medium-term actions. The focus is on measures to prevent and reduce emissions, for example through optimized energy efficiency in our buildings and more climate-friendly means of transport. Unavoidable emissions will be offset by suitable mechanisms. To measure our progress, we assess our carbon footprint annually. The next sustainability report, to be published in 2024, will include information on the progress.

With our climate strategy, we want to live up to our corporate mission “to improve human living conditions” and set out the course for Eppendorf’s future.

Meaningful performance indicators

We already capture various performance indicators as part of our environmental management activities, including total energy consumption and energy efficiency in relation to parameters such as area, production output, material input and employee headcount. These performance indicators are captured, analyzed and evaluated annually at the locations that already hold ISO 14001 certification and at those currently working towards certification. We monitor the development of these indicators for insight into the impact of our climate action and efficiency measures. An overview of the reported key performance indicators appears in the section entitled Key Sustainability Indicators.

Efficiency gains: energy audits mark the starting point

Concrete actions to improve energy efficiency can already be identified based on energy audits, which we perform every four years at our most energy-intensive locations in Germany. Since 2015, we have performed two audits at each of our three largest German sites. The next audit will take place in 2023. The results of the audits are analyzed, and our findings are then incorporated into a plan of action that is implemented in stages by the location managers. Implementation is subsequently monitored as part of our Environmental Management Efforts.

Roles & responsibilities

Responsibility for climate action rests with our Chief Financial Officer (CFO), who is in charge of this subject within the Management Board as a whole. The entire Management Board makes strategic decisions and approves specific actions. The development of our climate strategy, carbon footprint tracking and the implementation of all climate actions are handled by the Sustainability & HSE unit. Experts from the specialized departments develop concrete measures and implement them once they are approved.

Relevant standards & guidelines

The Eppendorf environmental and safety mission (HSE Mission) serves as the framework for our environmental actions as a company, and it applies throughout the organization. It stipulates that measures to reduce and prevent environmental impact should be identified, implemented and checked on an ongoing basis to assess their effectiveness. We achieve this goal through our certified environmental activities based on the ISO 14001 standard. Our environmental management system allows us to achieve systematic improvement in our environmental performance and manage change processes effectively.

All sites that hold ISO 14001 certification undergo regular audits in keeping with applicable laws, permits, and internal company guidelines. Energy audits are performed every four years.

Improving processes, optimizing products

We take a two-pronged approach to climate action: First, we reduce CO2 emissions from our business processes and transportation and travel activities. For example, we purchase electricity from renewable sources and implement energy efficiency improvements. Second, we aim to reduce CO2 emissions during our products’ use phase by taking actions such as developing more energy-efficient products. We plan to ramp up company-wide dialogue around climate action.

Eppendorf has supported the KlimaWirtschaft Foundation since 2022. The foundation’s aim is to promote climate protection and the sustainable use of natural resources. Industry is expected to play a central role and contribute to the solution. The member companies of the foundation meet several times a year to discuss issues together and to provide impetus for policy makers.

In addition, we are a founding member of the Unternehmensnetzwerk Klimaschutz (company network for climate protection) of the Association of German Chambers of Industry and Commerce (DIHK), which brings together companies that want to invest in sustainability. The members can acquire knowledge in the field of corporate climate protection, contact other companies and learn from each other's experiences.

Our carbon footprint

In our push to identify our carbon footprint, we began logging, analyzing and evaluating the total energy consumed by our internal business processes (electricity, heating/cooling energy, fuel for our vehicle fleet) in 2021. As an additional factor in our carbon footprint analysis, we also collected information on the CO2 emissions arising from transportation that we commission, as well as business trips taken by plane (Scope 3, categories 4, 6 and 9). We chose 2019 as the base year for our carbon footprint, since the figures for 2020 and 2021 are not representative due to the restrictions brought by the COVID-19 pandemic. In total, Eppendorf was responsible for 106,920 t of CO2 emissions in 2019. The electricity used at the sites accounted for most of this figure.

Our CO2 emissions from air travel fell in both 2020 and 2021 due to the pandemic until they increased in 2022 again reaching 2,256 t. On the other hand, CO2 emissions from transport of our products fell by 24%, mainly due to replacing air freight with sea freight.

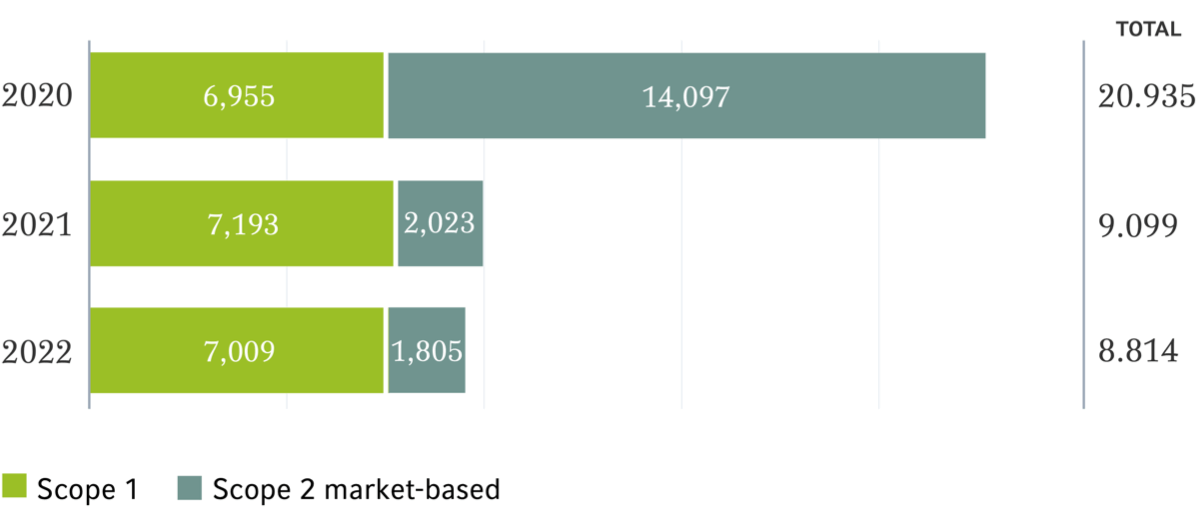

Scope 1 & Scope 2 emissions in t CO2

GRI 305-1, -2

(PNG, 23 KB)

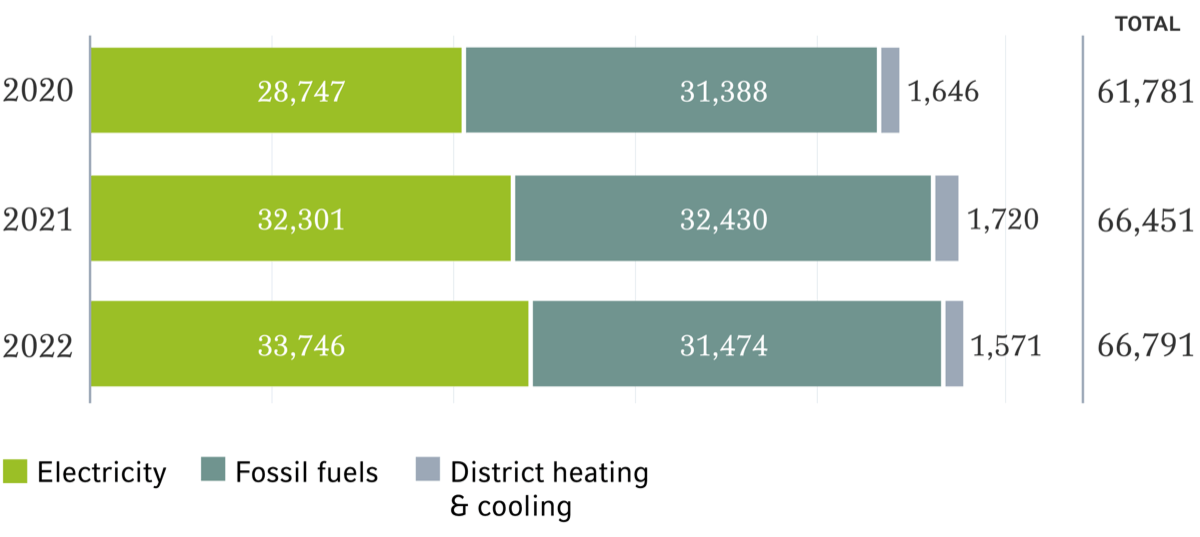

Eppendorf Group energy consumption in MWh

GRI 302-1

(PNG, 29 KB)

Moving toward climate neutrality

Sourcing energy from renewables is a core element of our push to reduce emissions. Most of the Eppendorf locations in Germany have been powered by “green” electricity since 2020. The only sites in Germany that were still using conventional electricity at the end of 2022 were our German sales company headquartered in Wesseling and the Eppendorf Distribution Center in Hamburg. Together, these two sites accounted for less than 4% of the total electricity consumed by Eppendorf in Germany in 2022.

By purchasing 38.6 million kWh of certified “green” electricity, Eppendorf has achieved climate neutrality in terms of calculated electricity use at five sites in Germany for the period from January 1, 2021, until December 31, 2022. This translates to 16,354 t less CO2 emitted to generate this volume of energy compared to emissions expected from common, average power sources in place in Germany at the time that the certificate was issued.

Locations outside Germany are also powered by renewable energies. Our production site in Enfield, USA, has been operated with 100% wind energy since 2021. Maldon in the UK uses 100% “green” power since 2020.

Renewable energies & energy efficiency at our locations

In addition to sourcing our electricity from renewables, we are increasingly generating our own power. In Hamburg, for example, solar panels were installed on the roof of one office building in 2014, supplying energy to power the heat pumps in a geothermal power system.

A new building at the Jülich location has been constructed since October 2021 to the Platinum standard of the German Sustainable Building Council (DGNB), the highest standard of sustainable building. Certain criteria must be met for this standard, for example with regard to the life cycle assessment of the building, the use of recycled building materials and the indoor air quality. In Jülich, a green roof promotes a pleasant building climate and helps save energy costs. On sunny days, a photovoltaic system generates more energy than consumed by the 3,600 m² building. The building also meets KfW efficiency level 40 Plus, the top efficiency level involving in-house generation and use of electricity. The primary energy demand is 60% lower than for a comparable conventional new building. As soon as the employees will have moved into the new building in the third quarter of 2023, the existing buildings at the Jülich location will also be refurbished and modernized.

As part of the Management Board resolution, which was executed with the adoption of the Eppendorf 2025 strategy, the DGNB “Platinum” standard was set as a target for construction projects in the EMEA economic region. For building projects outside the EMEA region, we seek to achieve the Leadership in Energy and Environmental Design (LEED) gold certification. The Jülich location is the first construction project to meet the requirements of the DGNB “Platinum” standard. This will be followed by the construction of the Technology Center Shanghai, which is aiming for the standard of LEED Gold certification.

We are also hard at work in various ways to improve energy efficiency in administration and production. At the Oldenburg site, for example, we commissioned an advanced combined heat and power (CHP) plant back in 2014. The plant supplied 25% of the electricity and 58% of the cooling needed at the plant in 2022. Additional measures included replacing or insulating window fronts during renovation activities and forging ahead with the shift to LED lighting. At the Hamburg location, we have developed an optimization concept for compressed air generation and implemented it in the course of 2022. This involved the replacement of compressors and an improved compressor control. In Leipzig, LED lighting was added to the production facility in 2022, which had already been converted in 2021. At our site in Maldon, UK, we reuse the waste heat generated in the process of quality checks of our ultra-low-temperature (ULT) freezers.

Since the year under review, augmented reality (AR) glasses have enabled both digitally innovative and energy-efficient collaboration of our Technology Centers in Oldenburg and Enfield. Production workers communicate with technical experts via video phone calls. The productions workers wear AR glasses, which transmits an image, in which markings can be placed and special plant parts can be shown precisely. This way, technicians and employees from production can see the same thing at different locations and find solutions together, for example in the case of error messages. This saves time because explanations on the phone without an image would be less understandable and more time-consuming. The use of AR glasses also reduces environmentally harmful business travel. Moreover, this method can be used for simplified individual training on devices and software programs.

Employee mobility

To lower the CO2 emissions generated by our business activities, we also focus on our employees’ mobility, particularly in Germany. Our goal for our fleet of vehicles in Germany is to achieve an average of 40 g CO2/km by 2025.

At the end of 2022, the average was 73 g CO2/km (2021: 101 g CO2/km). To further reduce our fleet’s CO2 emissions, plans call for procurement of further hybrid and electric vehicles for all sites in Germany.

In May 2021, we began shifting all company vehicles at our locations in North America to hybrid options as soon as the leases expire. Since the introduction of our CarPolicy in December 2020, CO2 emissions of our fleet have already been reduced by 43.4%.

We introduced our "JobRad" program for employees at our German locations in 2021. The new program allows employees to lease a bicycle for a 36-month term and make installment payments through deferred compensation. By the end of 2022, 278 company bikes had been purchased under this initiative, 100 of which were acquired in the year under review.

Construction work on a new bike parking building got under way at the Hamburg site in 2021. In the year under review, the bikestop building was opened and now offers space for a total of 310 bikes and six bikes with trailers. There is also a sufficient number of charging stations for electric bikes and two service stations equipped with a lift apparatus and air pumps. All this is part of our efforts to support the shift away from cars and make it easier for our employees to choose alternative modes of transportation.

Lowering environmental impact during product development & use

Our climate action efforts are geared toward reducing CO2 emissions during the phase when our products are in use (Scope 3, category 11). Various internal analyses have shown that a considerable portion of our emissions arise during this phase. During the period under review, customers’ use of Eppendorf brand products gave rise to approximately 246,561 t of CO2. In addition, the extraction and production of purchased materials contribute a significant share of upstream emissions, i.e., those from the upstream value chain. For this reason, Eppendorf pays attention to the efficient use of material in the production process. We also aim to raise awareness of energy conservation among our customers through publications. The exceptionally high durability of our products is another key factor in reducing their carbon footprint.

Eppendorf has been working with My Green Lab®, an independent nonprofit organization, within the scope of the ACT® Environmental Impact Factor Label since 2017. ACT® certifications satisfy the growing demand among researchers and procurement market companies for transparent information, verified by third parties, on the environmental impact of laboratory equipment. The certifications take into account sustainability criteria from the production of a product to the end of its service life – such as resource efficiency, the use of materials from renewable sources, recycled content, durability of the products and recyclability. Eppendorf is proud to have its products certified by My Green Lab® as another way to demonstrate that we are pursuing continuous improvement.

In 2022, multiple Eppendorf products earned certification or re-certification. Among others, the BioBased Tubes and the ultra-low temperature (ULT)freezer (CryoCube® 440h) obtained ACT® certification. In 2018, the Eppendorf freezers became the first ULT freezers to earn certification under the ACT® label. Eppendorf plans to continue to expand on its cooperation with My Green Lab® and to obtain further certification for Eppendorf products in the future.

Our CryoCube F440n and F570n freezers, launched in 2021, use propane and ethane as natural refrigerants. Both hydrocarbons have very low global warming potential. The previous versions had used substances with much higher potential to contribute to global warming. This is an especially important factor as refrigerants, in the event of improper disposal, can potentially be released into the atmosphere. In the case of the CryoCube F440n freezer, we also increased capacity from 410 L to 440 L even as we lowered the daily energy consumption from 10.8 kWh to 8.3 kWh, resulting in a CO2 reduction of about 0.25 t per unit per year. We also lowered calculated electricity consumption by about 21% for the CryoCube F570n freezer, achieving an average reduction in CO2 emissions of about 0.22 t per unit per year.

Because ultra-low-temperature (ULT) freezers have to maintain ultra-low temperatures of -80 °C 24 hours a day, even energy-efficient units use large amounts of electricity. The International Institute for Sustainable Laboratories and the nonprofit organization My Green Lab® have joined forces to study ways to optimize the use of ULT freezers from an energy standpoint. To that end, they have launched an annual Freezer Challenge, which has already been sponsored several times by Eppendorf as a manufacturer of ULT freezers.

Users of ULT freezers are invited to take action to conserve energy and submit their results to the challenge. Measures to achieve this include efforts such as sharing a unit with colleagues or adjusting the target temperature. Awards are granted annually to the participants who have achieved the greatest energy savings through these actions. In 2022, approximately 1,500 laboratories from the USA, Europe and other regions of the world participated in the Freezer Challenge.